Design files for this project can be found here

Update 11/1/2017 – Updated design to revision C with better toolpaths

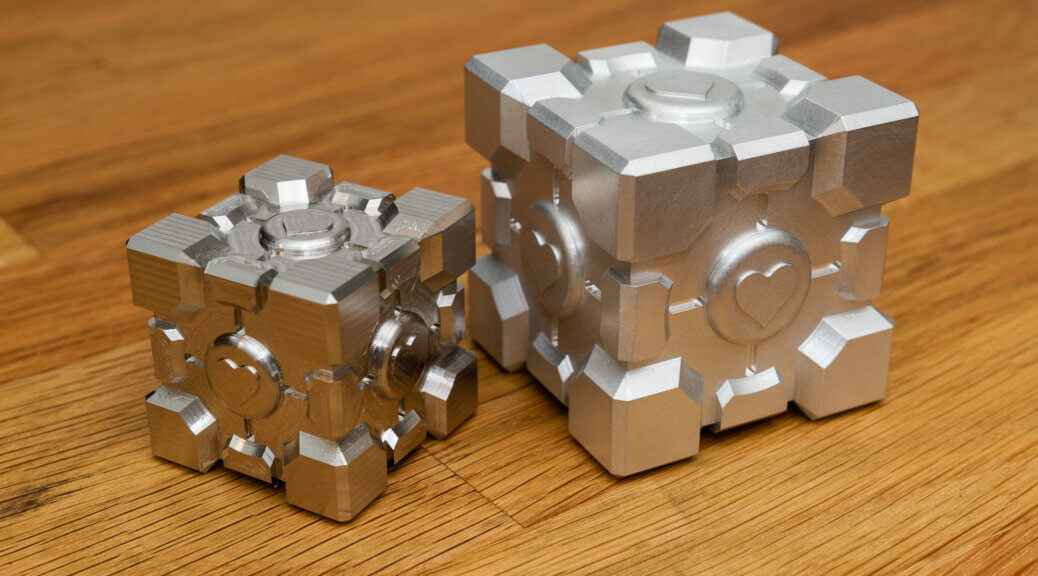

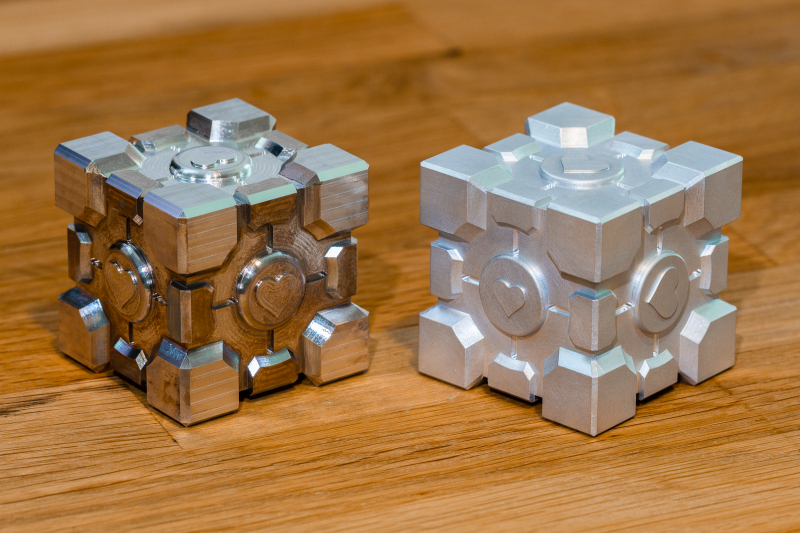

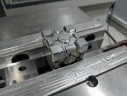

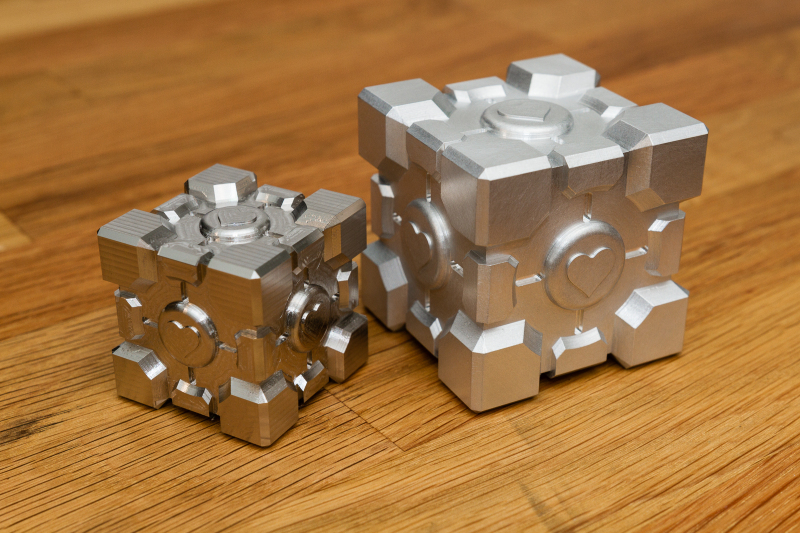

Another project on the Tormach P770: milling the Portal Companion Cube out of both 6061 aluminum and 316 stainless steel. Ended up breaking a few endmills as this was my first time milling stainless steel on the Tormach, but otherwise no major issues were encountered.

Revision A

The initial cube was made using an old model from a few years ago so it only took ~12 hours or so to generate the toolpaths, square the stock, and machine the cube. The cube was then cleaned up with some oxalic acid and a brass brush. The model used here was originally created in Inventor without using parametric modeling, so changing individual features was significantly harder than it should have been.

Revision B

The model had some slight changes made to it in the second revision, but the main goal was to convert everything to a fully parametric model in Fusion360 to make it easier to resize and change individual features of the cube. Two individual cubes were made, a 2″ version out of 6061 aluminum and another 1.5″ version out of 316 stainless steel.

Revision C

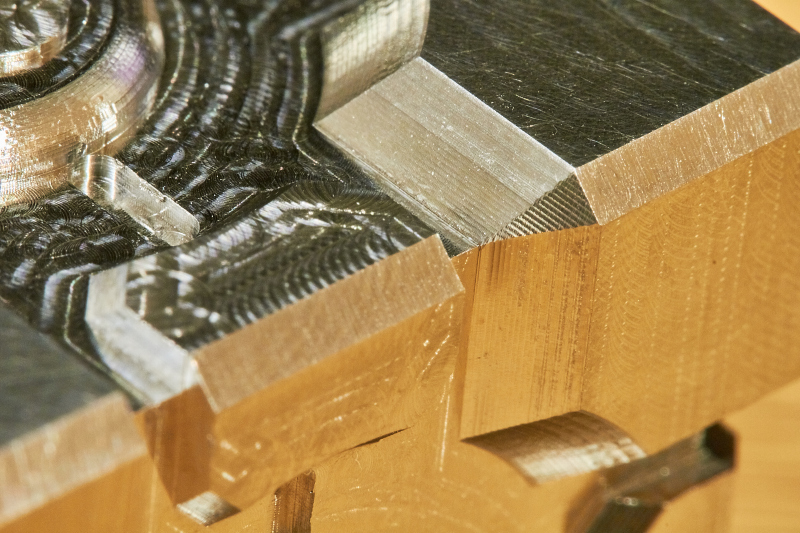

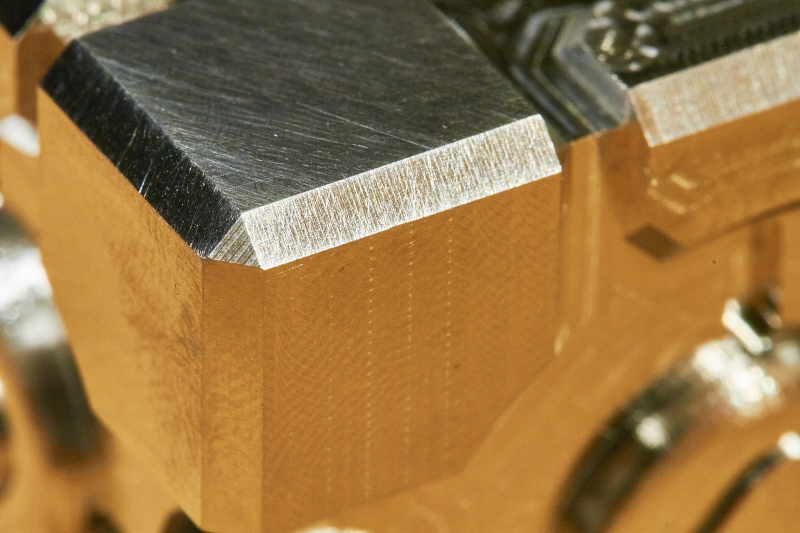

Improvements for this revision mainly involve the the toolpaths, with a focus on minimizing overlap to improve results when rotating/machining adjacent sides of the cube. Model parameters were also tweaked to allow for use of standard angle chamfer endmills in place of a ball mill for higher quality surface finishes on the draft faces. Three different chamfer endmills of 45°, 35°, and 22.5° are required.