Design files for this project can be found here

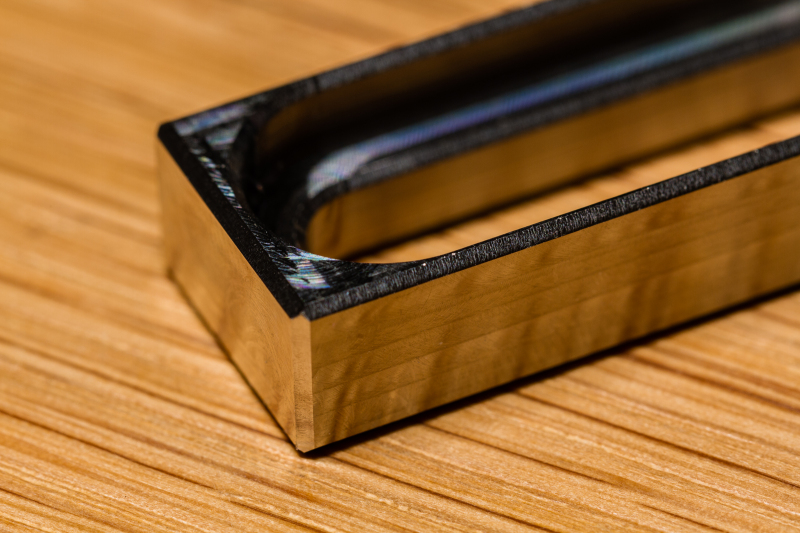

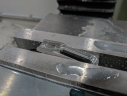

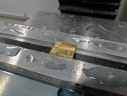

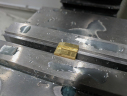

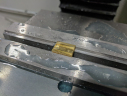

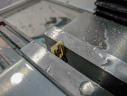

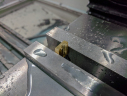

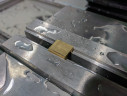

One of the major drawbacks with a fixturing table is that it is difficult to mount a piece of stock in such a way that you have access to the entire top of the stock. With my fixturing table and top-down clamps, a flat piece of stock can be easily secured, but the top-down clamps limit the machinable area. Most CNC machines get around this via a vise mounted to the table, but due to the limited work area of the Roland this was not a feasible approach. Instead, I designed and machined out custom toe clamps to securely and accurately hold parts down from the sides.

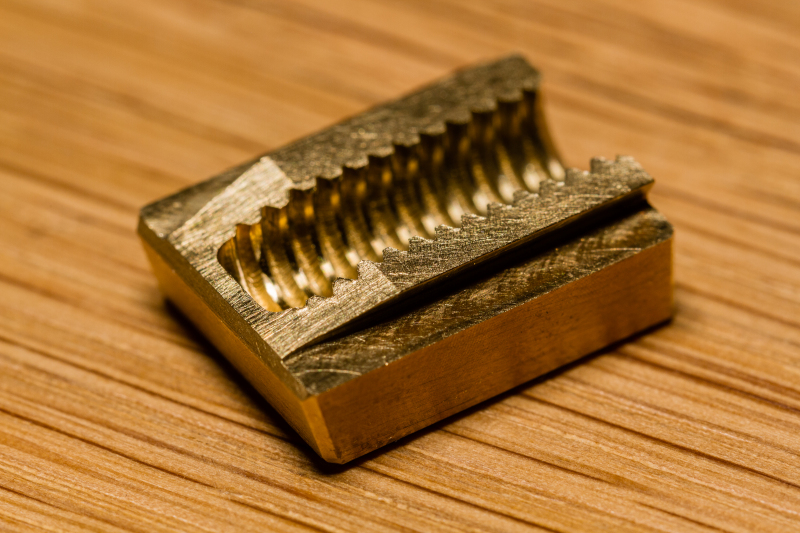

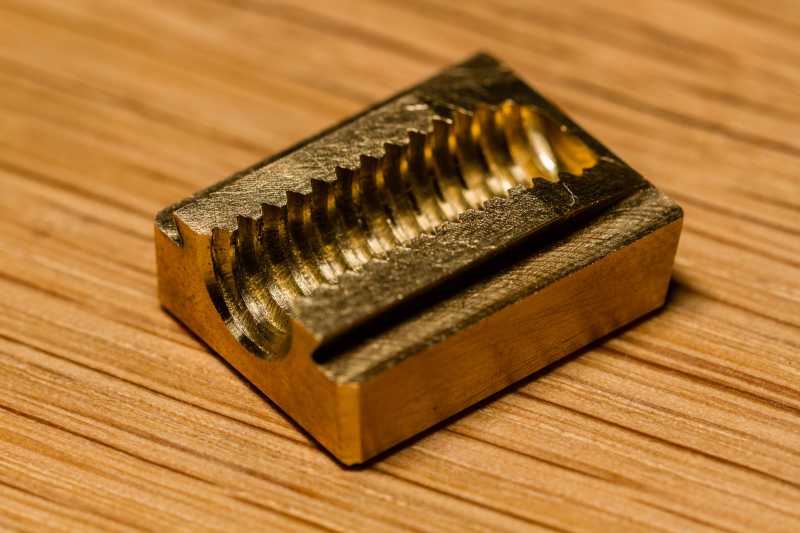

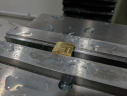

The base piece was machined out of 316 stainless steel while the head was machined out of C360 brass. The base has a slot to hold a 0.5in 1/4-20 set screw that move the head forward when turned (similar to a worm gear).