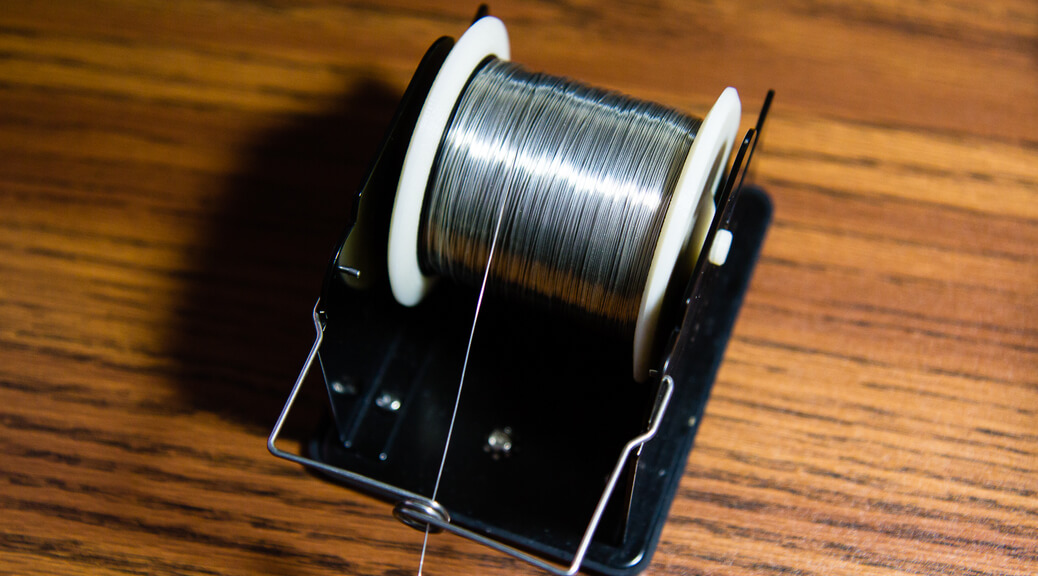

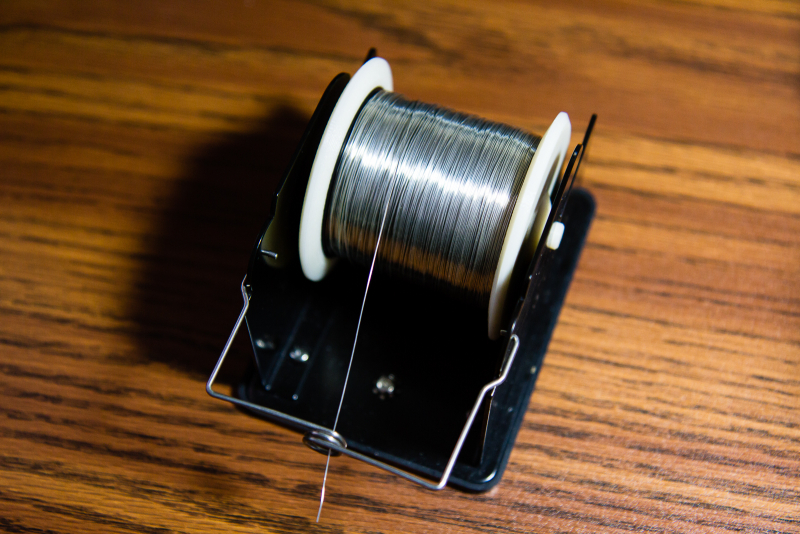

For those of you who are familiar with Hakko’s solder roll holder, you probably know how frustrating it gets when the wire decides to shift off to the side and wrap around the center axis. Since this happens pretty often and requires a significant amount of time to fix whenever it happens, I decided to come up with a solution that would completely fix the problem.

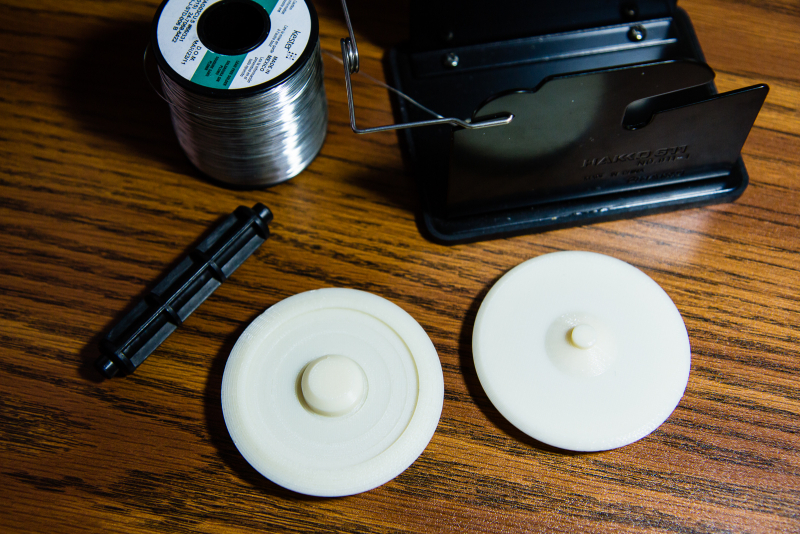

My solution to this problem involved two parts. The first was to create a wider barrier on the side of the solder roll to keep the wire from sliding off. This was done by 3D printing a replacement for the center axis piece. Instead of a single axis in the middle, two halves were designed to snap onto the edge of the roll of solder. This not only provided a wider rim, but with tight tolerances it also prevented the roll of solder from moving around.

The second was to put a bit of tension on the wire itself to reduce the amount of slack. It’s not visible in the photos, but I took a thin piece of cardboard with a small hole in the middle and stuffed it between the wire loops of the holder. This provided enough just enough resistance onto the wire to prevent it from moving backwards after being released. Combined, these two parts were able to completely fix the issue.

The STL files can be found in my SVN repository under “CAD Files/Solder_Holder”. The design itself was done in Autodesk Inventor.